In today’s construction landscape, building for durability, strength, and compliance is essential. That’s why we’ve made the strategic decision to transition from SS50 Structural Grade 50 steel to HSLA Grade 50 galvanized square tubing. This change enhances our structures’ quality, ensuring they meet today’s high-performance standards. Here, we’ll break down the differences between SS50 Structural Grade 50 and HSLA Grade 50, exploring why the switch to HSLA is a game-changer for durability and reliability.

Understanding SS50 Structural Grade 50 Steel

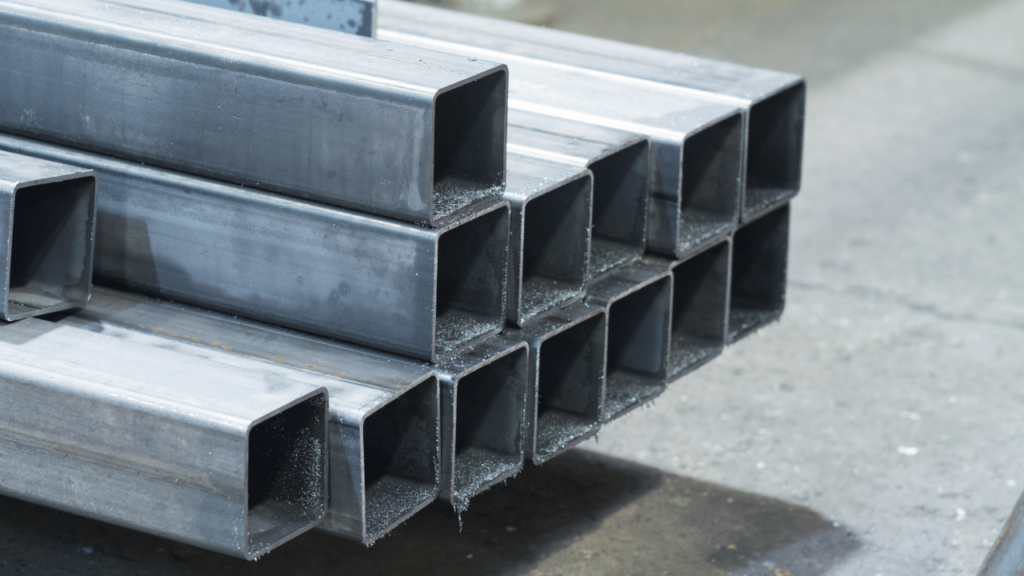

SS50 Structural Grade 50 steel tubing has long been a trusted material in construction. Its moderate strength and basic corrosion resistance made it ideal for general-purpose structures that didn’t require high tensile strength.

Key Characteristics of SS50 Structural Grade 50 Steel:

- Strength: Designed for general applications, SS50 steel tubing offers moderate strength suitable for standard construction needs.

- Corrosion Resistance: While resistant to some corrosion, SS50 isn’t galvanized, making it susceptible to rust over time, especially in exposed outdoor environments.

- Cost: As a more economical option, SS50 is favored in applications where budget is prioritized over longevity.

Why HSLA Grade 50 Steel Tubing is the Better Choice

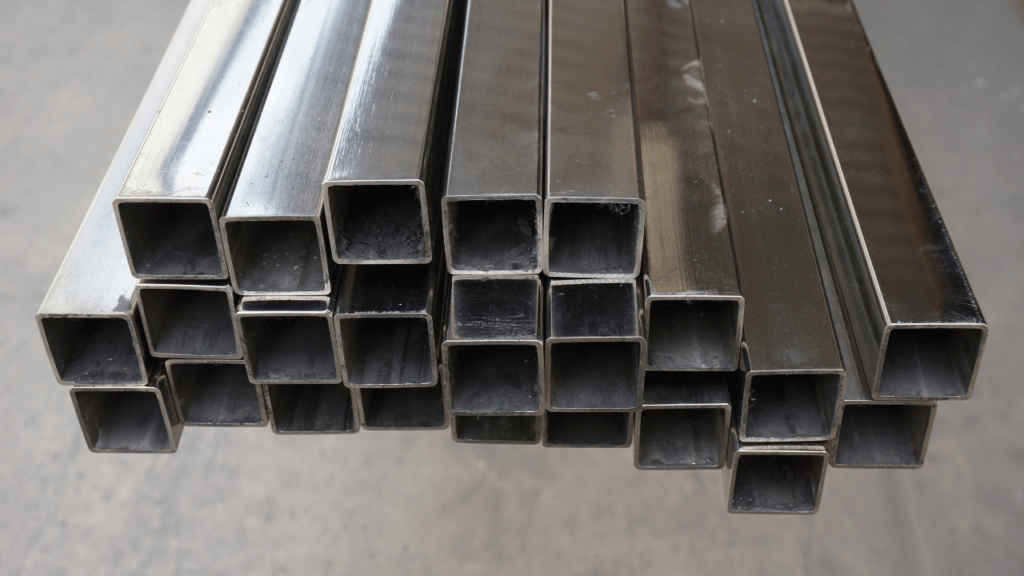

High-Strength, Low-Alloy (HSLA) Grade 50 steel tubing has emerged as a top choice for applications demanding both strength and resistance to environmental wear. Here’s how it surpasses SS50 on multiple fronts:

Key Benefits of HSLA Grade 50 Steel:

- Enhanced Strength and Structural Integrity

HSLA Grade 50 steel is a high-strength alloy that can handle greater loads and stresses than SS50. It’s designed to withstand significant pressure, making it ideal for outdoor structures in areas with severe weather. - Improved Corrosion Resistance

This steel tubing is galvanized, adding a protective zinc layer to resist rust and corrosion in harsh environments. Galvanization ensures the tubing remains structurally sound even after years of exposure to the elements. - Higher Industry Compliance Standards

As building codes evolve to address safety and longevity, HSLA Grade 50 tubing meets or exceeds the latest industry standards. It’s especially valuable for meeting high-wind and seismic building requirements, which are essential for many regions. - Longer Service Life

HSLA Grade 50’s composition makes it a more durable choice over time, reducing the need for repairs or replacements. While initially more expensive, this material can lower long-term costs, offering better value for customers.

SS50 vs. HSLA Grade 50: A Side-by-Side Comparison

| Feature | SS50 Structural Grade 50 | HSLA Grade 50 Galvanized Steel |

|---|---|---|

| Strength | Moderate, for general applications | High strength, suitable for demanding conditions |

| Corrosion Resistance | Basic, susceptible to rust outdoors | Galvanized, resists corrosion effectively |

| Compliance with Standards | Meets standard regulations | Exceeds standards, ideal for severe climates |

| Cost Efficiency | Lower upfront cost | Higher initial cost but better long-term value |

| Service Life | Moderate, may require more maintenance | Extended, low-maintenance with higher durability |

Investing in the Future: Why HSLA Grade 50 Steel is Worth the Cost

While the transition to HSLA Grade 50 has resulted in a modest increase in production costs, the benefits it brings—strength, resilience, and longevity—justify the investment. Structures built with HSLA Grade 50 require fewer repairs and replacements, offering significant savings over time.

What Does This Mean for Metal Building Manufacturers?

Our commitment to adopting HSLA Grade 50 steel tubing reflects our dedication to providing customers with the highest quality and most durable structures possible. By choosing HSLA-enhanced products, you’re investing in reliability, reduced maintenance costs, and peace of mind knowing your structure meets today’s rigorous standards.

The Lasting Impact of Upgrading to HSLA Grade 50 Steel

Upgrading to HSLA Grade 50 galvanized steel tubing marks a commitment to quality and longevity. We believe this shift will continue to deliver unparalleled reliability, proving the value of investing in premium materials for our customers’ peace of mind.